|

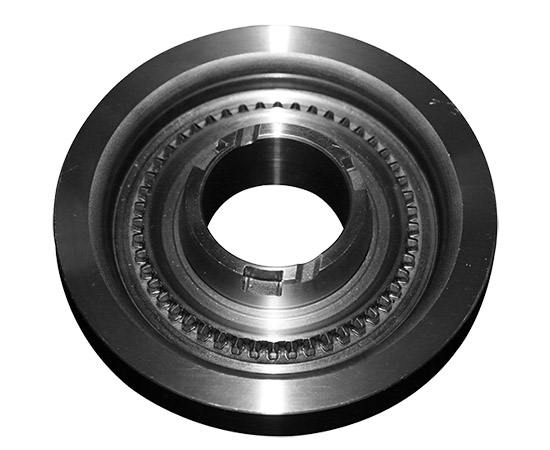

Up to now, there are over 300 models developed and manufactured, supplied to 15 OEMs. Synchronizer engagement tooth of over 100 models are supplied as per 100%, Chongqing Chuangjing precision monoblock gear series product Ranked First in domestic market share.

1. Compare the forging press fit with the sub-body structure and sub-structure combination of welding gear :

◆ high strength, reliability, and can stop completely the welding process Weld, loose weld

phenomenon, the product of safety is good;

◆ Reducing machining sequence, improving the production efficiency and reducing the logistics process and the site occupancy, reducing the input of machining equipment;

◆ Shifting resistance, shifting more smoothly;

◆ Spline tooth is forming, metal flow lines are not cut, mechanical strength increased wear resistance.

2. Performance index of precision formed conjunction gear.

◆ Involute spline of cylinder gear has reached national percision level 6(GB/T3478.1-1995).

◆ Runout precision of gear ring is Frs≤0.06mm.

◆ Precision of reversed cone angle is within ±30′.

◆ Mechanical strength has increased 25%.

|